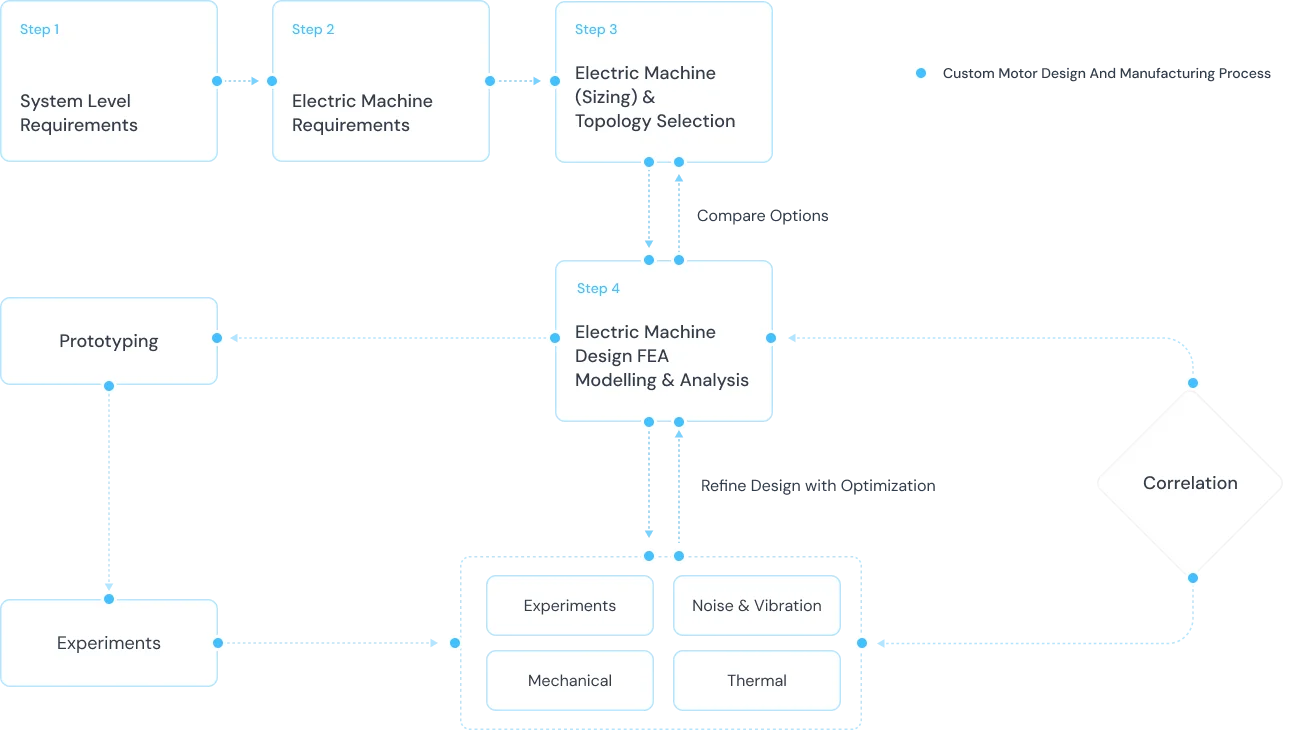

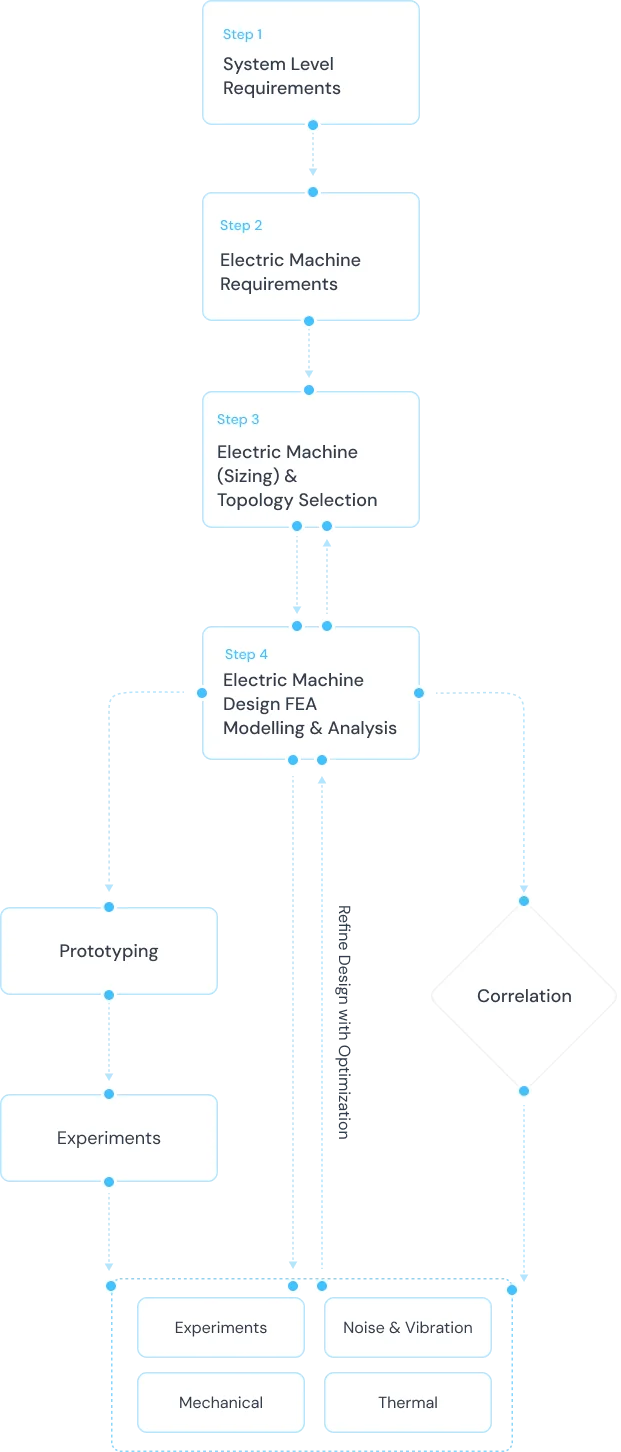

iNetic prototyping services help clients turn their innovative motor designs into reality. We provide comprehensive prototyping capabilities, working closely with clients throughout the development process.

Our experienced team collaborates closely with clients to develop motors that meet their precise specifications. We use cutting-edge technology and robust materials to enhance performance, efficiency, and longevity. Furthermore, we offer the option for Intellectual Property (IP) transfer, allowing clients to retain full ownership of their custom motor designs. This ensures that our clients can protect their innovations while benefiting from our advanced manufacturing capabilities.

Contact Us