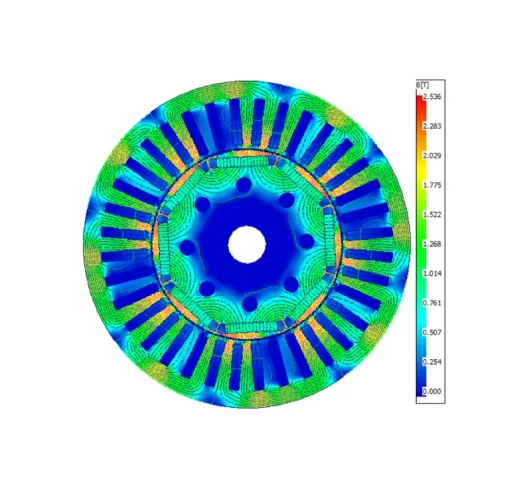

Our designs cover all specification aspects, including thermal peak and steady-state conditions, and coolant flow management. We conduct extensive analyses, such as short circuit, demagnetization, thermal simulation, and torque ripple assessment, to guarantee reliability and longevity. Harmonic distortion and mechanical strength are addressed with fatigue testing and tolerance analysis, enhancing design accuracy with high-fidelity map generation.

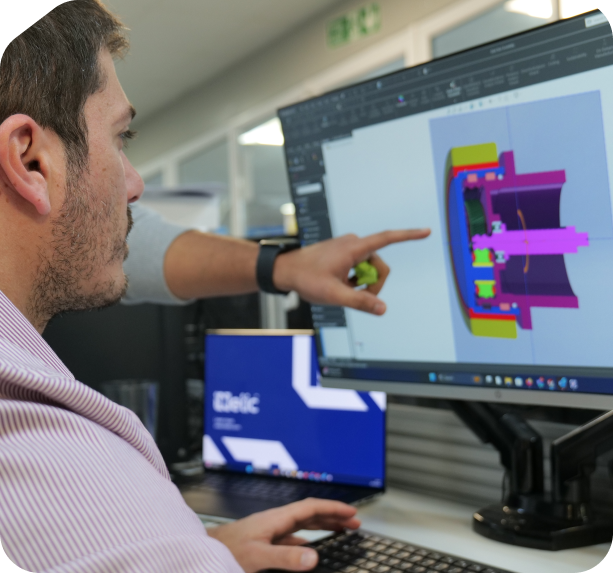

Utilizing Design for Manufacturing (DMF) principles, we ensure cost-effectiveness and efficiency. All design activities comply with AS9100 standards, ensuring high reliability in demanding Aerospace environments.

By combining these capabilities, iNetic delivers motors that excel under challenging conditions, providing unparalleled reliability and efficiency.